CELO, global industrial fasteners and screw manufacturer

CELOPLAST screws

When to choose CELOPLAST screw?

CELOPLAST screws provide higher pull-out resistance, improve ergonomics and avoid deformation of plastic bosses, greatly enhancing the technical properties of self-tapping screws. These advantages are obtained by a combination of technical features specifically designed for plastic assemblies.

CELOPLAST screws are being replaced by the new CELOspArk® offering an improved screw performance in the assembly of ductile plastics.

Benefits

- Less radial tension of plastic. It allows for bosses with smaller diameter and reduces the problem of boss bursting.

- Quick alignment of the screw before screwing in, thus reducing assembly time.

- Lower thread forming torque, which provides a more ergonomic assembly.

- More resistant to pull-out and stripping, which enables its use in assemblies with high pull-out resistance and/or compression requirements.

- The increased contact surface between threads and nut member improves vibration loosening resistance.

- Screws can be reused with a reduced risk of stripping.

All of these benefits together provide a more resistant assembly, greater safety during threading and lower costs of the assembly process.

Downloads & Services

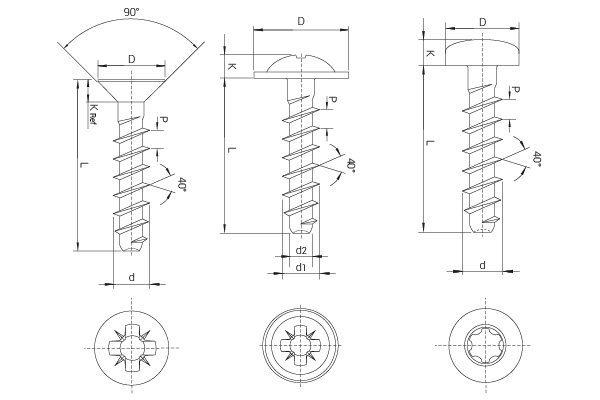

Screw design specifications

We produce customized CELOPLAST screws to fit your exact requirements. To improve their functionality, CELOPLAST screws can be produced under different head designs, recess, dimensions and coating configuration.

Additionally, we offer a wide range of CELOPLAST screws in stock for immediate delivery.

For further information on the options available, please contact our application engineers.

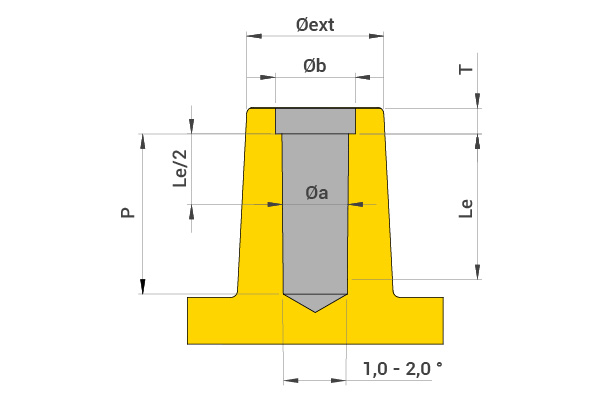

Boss Design Guidelines

In order to ensure a safe installation and stable clamping force, it's relevant to pay attention to the boss design.

The recommended dimensions for core hole diameter and length of engagement are available at Design Guidelines.