CELO, global industrial fasteners and screw manufacturer

FASTITE® 2000™ screw

When to choose FASTITE® 2000™ screw?

The increasing demand for weight reduction and cost savings leads to the use of lightweight materials. FASTITE® 2000™ screws solve common fastening problems when joining thin metal sheet, assuring clamping force and stripping resistance whilst offering opportunities for cost reduction.

FASTITE® 2000™ screws are the best alternative to selftapping screws, rivets and caged nuts. The unique FASTITE® 2000™ thread rolling screws are the best cost-effective solution when joining steel and aluminum thin sheets with untapped holes. It offers a strong mechanical joint with excellent pull-out and vibration loosening resistance.

How does it work?

FASTITE® 2000™ TRILOBULAR® screws have been specially designed for the assembly into untapped holes in thin aluminium and steel sheets.

- Twin-lead helix provides starting stability.

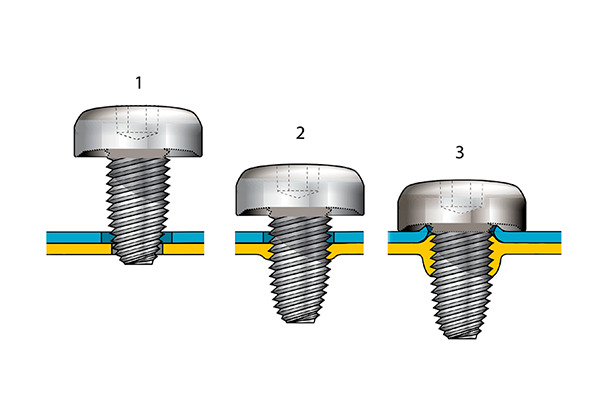

- Special extruding point increases the thread engagement length during screw insertion.

- Increased core diameter approaching the underside of the head causes additional forward and backward extrusion to increase thread engagement.

Benefits

- Eliminates the problem of stripping or loose assemblies with self-tapping screws: unthreaded length below the head is larger than the thickness of the assembly, causing the screw to clip the sheet.

- Assembly costs reduction by eliminating the thread tapping process when using machine screws and sheet extrusion.

- Optimized thread engagement provides high pull-out and vibration loosening resistance.

- Twin-lead thread increases stripping resistance.

- Clockwise under head serrations increase resistance to stripping.

- TRILOBULAR® thread section provides low threading torque and improves ergonomics.

- The special extruding point ensures an excellent alignment and hole finding, which provides a secure and tight assembly.

- Possibility of piercing thin materials with the optional cut off point.

- It is an efficient alternative to high cost elements as threaded inserts and caged nuts.

Downloads & Services

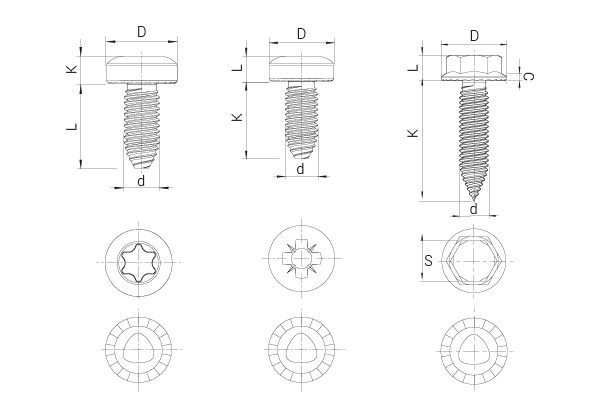

Screw design specifications

We produce customized FASTITE® 2000™ screws to fit your exact requirements. To improve their functionality, FASTITE® 2000™ screws can be produced under different head designs, recess, dimensions and coating configuration.

Additionally, we offer a wide range of FASTITE® 2000™ screws in stock for immediate delivery.

For further information on the options available, please contact our application engineers.

Products in stock

FT85T

FASTITE® 2000™ Zinc plated screw, Pan head with serrations TORX®

Go to the product

FT85Z

FASTITE® 2000™ Zinc plated screw, Pan head with serrations, POZI

Go to the product

FTA85Z

FASTITE® 2000™ Zinc plated screw, Pan head POZI, self-drilling point

Go to the product

FTPG

FASTITE® 2000™ Zinc plated screw, hexagonal flange head CUT-OFF point

Go to the productPilot hole diameter guidelines

In order to ensure a safe installation and stable mechanical resistance, it's relevant to pay attention to the pilot hole diameter.

The recommended dimensions for pilot hole diameter for different plate thickness are available at Design Guidelines.